Right when the dry season nears its end, buds on coffee plants dare to stick out a just a little, only waiting impatiently for the first rainfall in order to burst open to full bloom. That first rain of a rainy season, we learn, will also determine the time of harvest which makes it an important forecast for coffee farmers, not only here in this beautiful midland of Guatemala.

We visited Finca Colombia in Antigua Guatemala which has been family owned for the past 90 years. Our kind and deeply knowledgeable guide, Guisela, is a member of the family running this estate. She took us on a tour and explained the process of growing coffee, harvesting and processing it.

Antigua Guatemala, the former capital of Guatemala is situated on the so-called midland, at higher altitude than the coastal coffee growing region but lower than the highland coffee region in the mountains. “Anitgua Coffee” is the regional trademark of coffee coming from this central region of Guatemala.

Finca Colombia grows Arabica coffee of two kinds, Burbon and Caturra. The plants can be distinguished by height and vertical distance of branches. Burbon plants grow taller (approx. 2m+) and their branches are further apart. Arabica Caturra plants grow short and bushy instead.

Blooming. As mentioned before, blooming will start with the first rainfall of the rainy season. This rainfall also determines the time of harvest. Coffee plants have a white bloom of a citrusy smell. Guisela tells us that when the plantation is at full bloom it resembles a beautiful snow-covered landscape. Unfortunately the spectacle only lasts for about 8 days. Flowers are male and female at the same time and usually the wind and wild bees are sufficient to pollinate the plantation. The family trialed using beehives in addition to wild bees before but, as Guisela explained, there was no significant impact on the plantation so they stopped the effort.

Blooming. As mentioned before, blooming will start with the first rainfall of the rainy season. This rainfall also determines the time of harvest. Coffee plants have a white bloom of a citrusy smell. Guisela tells us that when the plantation is at full bloom it resembles a beautiful snow-covered landscape. Unfortunately the spectacle only lasts for about 8 days. Flowers are male and female at the same time and usually the wind and wild bees are sufficient to pollinate the plantation. The family trialed using beehives in addition to wild bees before but, as Guisela explained, there was no significant impact on the plantation so they stopped the effort.

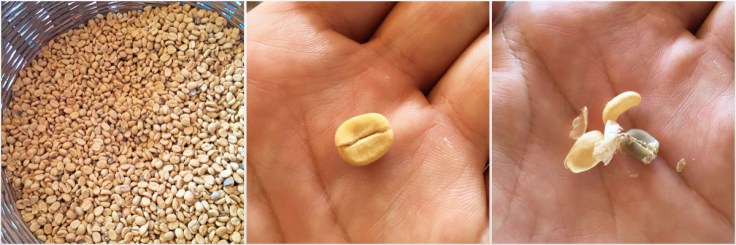

Harvesting. During the ripening process berries go from green to either red or yellow, what however is irrelevant for the taste. It takes nine months for plants to progress from bloom to ripe berries, meaning there is only one harvest per year. Each berry typically got 2 seeds (coffee beans) inside.

The harvest itself, which is done by hand, is mainly performed by women and teenagers while men have to go about their permanent jobs. Pickers have to be very careful to only pick ripe berries as a single green berry in a batch of coffee could ruin the taste. Therefore there are several checkpoints throughout the process to avoid this to happen. On a picking day, for the purpose of alignment, the supervisor would blow a horn in regular intervals, which indicates to pickers to return to pathways to empty their baskets. Berries are poured on a big cloth and carefully checked for wrongly picked green beans.

Guisela explains that the different sections of the farm keep coffee plants of same age together. That’s important as coffee plants required different treatment throughout their lifecycle. A plant is typically used for more than 30 years. As not all berries ripe at exactly the same time a harvest consists of about three rounds of pickings and therefore takes about 3-4 months to be completed. At the time the late berries would ripe, the following rainy season kicks off and plants already start to bloom for the next cycle. Pickers have to be extra careful to not harm the flowers. It was also interesting to hear that dead leaves would remain on the ground for two reasons, to control moisture and to turn into compost.

One plant produces about 25-30 pounds of coffee berries per year. Finca Colombia’s 36 acres farm would produce about 200,000 pounds of ripe coffee berries each year. This volume would shrink to about a forth before the coffee will hit the roastery.

Processing from berries to coffee

The process of processing berries to coffee beans ready for shipping covers two main steps: 1. wet mill, 2. dry mill. The initial wet mill process involves water, therefore the name. Berries get dumped into a big water tank  where water pushes berries down into a pipe leading to a machine squashing the berries open. The continuous water pressure pushes seeds and the peel towards a grid where the actual separation takes place and only the seeds get pushed out into tanks. Interestingly, for reasons of either size or air inclusions some beans don’t get crushed open during the first run but require a second squeeze. Those will be immediately separated for 2nd quality coffee. The remaining peel in that process doesn’t get thrown away but used for making compost for the plantation.

where water pushes berries down into a pipe leading to a machine squashing the berries open. The continuous water pressure pushes seeds and the peel towards a grid where the actual separation takes place and only the seeds get pushed out into tanks. Interestingly, for reasons of either size or air inclusions some beans don’t get crushed open during the first run but require a second squeeze. Those will be immediately separated for 2nd quality coffee. The remaining peel in that process doesn’t get thrown away but used for making compost for the plantation.

The next step requires beans to ferment. The fermenting process takes place over 3 cold days and 2 cold nights. This is required to remove the sweet juice that still sticks on the beans from the berries. The fermenting leads to the beans turning black and smell rotten. After a washing cycle the beans are laid out on carpets in the sun over a few days to reduce moisture to about 12%. To achieve that beans have to be turned frequently as well as piled and covered for the night each day before spreading them out again in the morning. At this stage the coffee seeds are still encased inside the parchment envelop, which is a thin orange cover. Once the right level of moisture has been reached, these type of beans are referred to as “parchment coffee”.

Subsequently in the dry mill a process called “hulling” removes the orange colored husk from the beans and delivers green beans. A final step of sorting and grading the beans is required before they are filled in jute or sisal bags and made ready for shipping. Those green beans are what roasters around the world would purchase and start from.

Asking Guisela about the biggest challenges they face every year she refers to a fungus. Two years ago such a fungus spread quickly due to wind which lead to a significant infection. A 4th of the whole plantation had to be trimmed in order to not loose the plants completely.

Leave a comment